Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

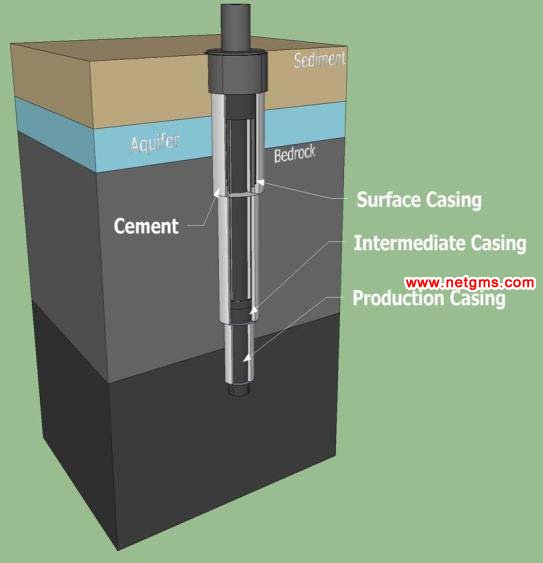

Conductor Casing | Intermediate Casing | Liner Strings | Production Casing

Conductor Casing

Conductor casing is installed initially, normally before the arrival from the drilling rig. The hole for conductor casing is generally drilled having a tiny auger drill, mounted around the back of a truck. Conductor casing is normally no greater than 20 to 50 feet extended. It is actually installed to stop the leading in the properly from caving in and to help in the course of action of circulating the drilling fluid up in the bottom with the well. Onshore, this casing is generally 16 to 20 inches in diameter, although offshore casing ordinarily measures 30 to 42 inches. The conductor casing is cemented into location prior to drilling begins.

Surface casing may be the next sort of casing to become installed. It may be anywhere from some hundred to two,000 feet long, and is smaller in diameter than the conductor casing. When installed, the surface casing fits inside the best with the conductor casing. The main goal of surface casing should be to guard fresh water deposits near the surface of the well from being contaminated by leaking hydrocarbons or salt water from deeper underground. It also serves as a conduit for drilling mud returning for the surface, and assists shield the drill hole from being broken throughout drilling. Surface casing, like conductor casing, is cemented into spot. Regulations frequently dictate the thickness in the cement to be used to make sure that there is certainly little possibility of freshwater contamination.

Conductor Casing | Intermediate Casing | Liner Strings | Production Casing

Intermediate Casing

Intermediate casing is normally the longest section of casing found in a nicely. The major objective of intermediate casing is usually to lessen the hazards that come as well as subsurface formations that may possibly affect the effectively. These involve abnormal underground pressure zones, underground shale, and formations that may well otherwise contaminate the nicely, which include underground salt-water deposits. In a lot of instances, even though there may well be no proof of an unusual underground formation, intermediate casing is run as insurance against the possibility of such a formation affecting the effectively. These intermediate casing areas may perhaps also be cemented into spot for added protection.

Liner Strings

Liner strings are often used rather than intermediate casing. Liner strings are normally run from the bottom of a different type of casing for the open well location. Even so, liner strings are often attached for the preceding casing with 'hangers', as an alternative to becoming cemented into place. This type of casing is therefore significantly less permanent than intermediate casing.

Production Casing

Production casing, alternatively named the 'oil string' or 'long string,’ is installed last and may be the deepest section of casing inside a properly. That is the casing that gives a conduit from the surface of your effectively for the petroleum-producing formation. The size from the production casing is dependent upon a variety of considerations, such as the lifting gear to be employed, the number of completions required, and the possibility of deepening the effectively at a later time. For instance, if it is anticipated that the nicely will likely be deepened at a later date, then the production casing have to be wide adequate to enable the passage of a drill bit later on.

Nicely casing is actually a crucial part of your completed nicely. Moreover to strengthening the effectively hole, it provides a conduit to enable hydrocarbons to be extracted devoid of intermingling with other fluids and formations found underground. It's also instrumental in stopping blowouts, permitting the formation to be 'sealed' in the prime should harmful stress levels be reached. For more technical info on blowouts and their prevention, click right here. As soon as the casing has been set, and in most situations cemented into place, appropriate lifting equipment is installed to bring the hydrocarbons from the formation towards the surface. Following the casing is installed, tubing is inserted inside the casing, running from the opening nicely at the best for the formation in the bottom. The hydrocarbons that happen to be extracted go up this tubing for the surface. This tubing could also be attached to pumping systems for additional effective extraction, must that be required.

上一篇:DIN2391 EN10305 DIN17175 steel pipe

下一篇:HISTORY OF SPIRAL WELDED STEEL PIPE AND SPIRALSTEEL PIPE INTRODUCTION

New Update Pipe List

-

API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

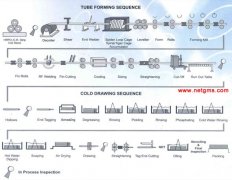

Hot rolled seamless steel pipe production.

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe