Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- sprial steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Quality Assurance

At Longtaidi Inc., we value product quality and customer satisfaction.

Other companies talk about quality and customer satisfaction, we have

30years of experience to back up our claim.

Our technicians design quality assurance procedures and see that they are

rigorously applied. They also make sure that all inspections of material and

workmanship are carried out in accordance with the required quality

assurance programs.

Longtaidi Steel Pipe Quality Assurance

As an ISO-certified company, Longtaidi is totally committed to innovative

and updated quality testing procedures and investing in the tools and

machines that provide the utmost in quality assurance. To that end, we have

extended our rigorous inspections and testing procedures through all stages

of the production process.

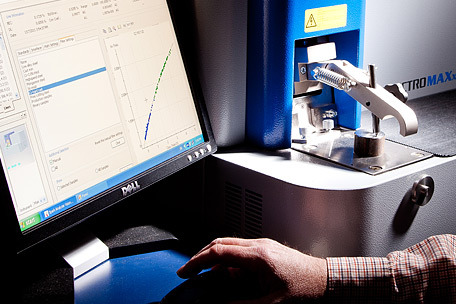

Laboratory Testing

In addition to in-line production inspections and tests, Longtaidi operates

a mechanical testing laboratory that performs the following tests:

Chemical composition with optical emission spectrometer:

Tensile test for material yield strength, percent elongation, and weld

tensile strength:

Charpy “V” notch impact test for percent shear area:

Charpy “V” notch impact test for energy absorption:

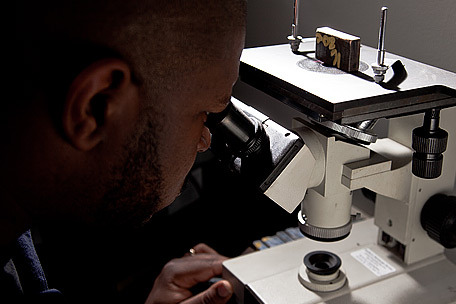

Microscopic examination of test sample of weld cross section:

Rockwell hardness test:

Micro hardness test for Vickers hardness:

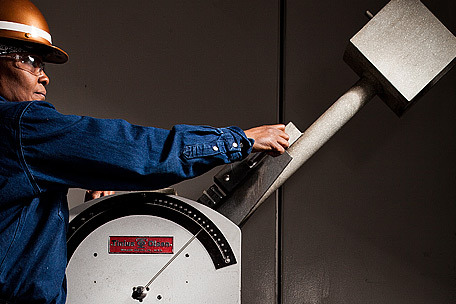

Drop weight tear test for percent shear area:

Guided bend test:

Flattening test:

Material Test Reports

At Longtaidi , all test reports are computer-generated and available

following final shipment. Your sales representative will be happy to discuss

any of these reports in more detail with you. Reports available on line pipe

manufactured to API 5L specifications:

Chemical analyses

Mechanical property tests

Fracture toughness tests

Data regarding skelp properties

Additional specific tests as requested by customer

Hydrotest

Line pipe is hydrotested to at least the API 5L specified minimum test

pressure. Longtaidi endeavors to hydrostatically test to 100% specified

minimum yield strength (SMYS) where possible. Pipe is tested with the weld

line facing up, and the trained HydroTest operator visually monitors the

entire weld line during testing.

Ultrasonic Inspection

Longtaidi provides our primary nondestructive testing for quality assurance

through the ultrasonic evaluation of the entire weld for each pipe.

Certified Training

The performance of the equipment and the application of this procedure is

the responsibility of Longtaidi's qualified ASNT-TC-1A, Level III. All

additional Longtaidi personnel who perform this testing are certified to

ASNT-TC-1A, Level II.

- Stainless pipe metrial

- 304, 304L, 304SS

- 310, 310S

- 316, 316L

- Pipe Fitting Metrial

- Carbon steel: A234 WPB

- Stainless steel: 304,316

- Alloy steel: A234 WP5 WP9 WP11 WP22