Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

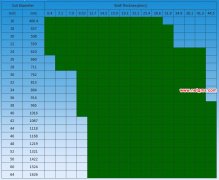

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

X80 pipeline,API X80 STEEL PIPE

X80 pipeline

Typical mechanical values taken from EBK pipes are given below:

Length: max. 42‘ (13.200 mm)*

Outside diameter: 16“-48“ (406 - 1.219 mm)

Yield strength Rt0.5: 552 - 690 MPa (in transverse direction)

Tensile strength Rm: 621 - 827 MPa (in transverse direction)

Hardness: max. 248 HV10

Elongation A 2“: min. 30%

CVN energy value: 42/34J at -20 °C (-4 °F)

Drilling riser, , line pipes, riser pipes, gathering lines, mother pipes for bend,wellhead houses

X80 pipeline steel containing molybdenum Kang Da deformation of two-stage cooling process control

Existing studies using low C steel component design with Mo, but also include other alloying elements Nb, Ti, Cu and Ni. Test steel vacuum induction furnace, vacuum casting and rapid cooling, heating and forging ingot is then hot-rolled into a rectangular slab.

Billet into the resistance heating furnace, and then incubated, after a four-roll mill rolling, after seven rolling into steel samples. Hot-rolled using recrystallization and recrystallization region controlled rolling two-stage process, the recrystallization rolling start rolling temperature and finish rolling temperature difference of about one hundred, the cumulative reduction rate> 60%; recrystallization region rolling start rolling lower temperatures and finishing temperature, the cumulative reduction rate> 70%.

Are using traditional pipeline after cold rolling fast direct cooling, organized into a single bainite, high strength and toughness, but the lack of plasticity; Kang Da deformation in order to obtain good performance ferrite - bainite duplex structure, study used a two-stage controlled cooling process: after rolling slowly at first air-cooled to a temperature below Ar3 to get some ferrite content; then accelerated into the water cooling, the remaining unconverted supercooled austenite into rapid cooling process bainite.

After a two-stage cooling process control, test with Mo ferritic steels get - bainite duplex structure, which includes ferrite polygonal ferrite and quasi-polygonal ferrite, granular bainite bainite.

Open cold temperatures accelerated cooling decided to organize content in ferrite: cold temperature decreases with the open, with Mo ferritic steels test volume fraction increases, the ferrite grain size increases; increasing the initial volume fraction of ferrite mainly caused by an increase in the amount of crystal nucleation, the latter is mainly caused by the grain growth. Final cooling temperature accelerated cooling effects characteristic of bainite organization: the higher end of the cold temperatures, bainite M / A island size is more thick, and many non-equiaxed; lower end of the cold temperatures, bainite M / A content decreased, finer size distribution is more uniform, homogeneous enhancement.

With the accelerated cooling of open cold temperature decreases, increasing the ferrite content, yield strength steels containing Mo drop test, the first increase in the reduced tensile strength, yield ratio lower, uniform elongation increased. When certain ferrite content, the main factors affecting the uniform elongation is characterized bainite M / A's. With the accelerated cooling stop temperature of the cooling is reduced, reducing the M / A content, size finer, fine and uniform distribution of M / A work hardening rate is increased to delay the occurrence of necking, the sample uniformly stretched while little change in intensity long was significantly improved.

上一篇:Structural steel pipe,Structural seamless pipe

下一篇:contactSS

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T .

Hot Click PRO

-

A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a.

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe