Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

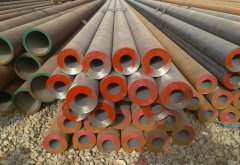

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

API 5L X70 Pipe,API 5L X70 Line pipe

API 5L X70 Pipe

We are making carbon steel seamless pipes and stainless steel welded pipes in quality material which are durable in use and long lasting. These steel pipes are fruitfully supporting and playing the main part in the pipe fittings where liquid flow is made possible and effective.

We have advanced production line where we are producing various types and categories of carbon steel seamless and stainless steel products for general and commercial uses.

Items

Seamless, ERW,

LSAW, EFW.

Specifications

ANSI B36.10, ANSI B36.19

Material Grades

Carbon Steel

ASTM A53 Gr. B, ASTM A106 Gr. B, ASTM A333, Gr.3, Gr.6

API 5LA, B, X42, X46, X52, X56, X60, X65, X70

| CHEMICAL COMPOSITION | |||||||

| Mass fraction, based upon heat and product analysis a | |||||||

| SEAMLESS PIPE | |||||||

| C | Mn | P | S | V | Nb | Ti | |

| maxb | max.b | min. | max. | max. | max. | max. | max. |

| 0.28e | 1.40e | - | 0.030 | 0.030 | f | f | f |

| WELDED PIPE | |||||||

| 0.26e | 1.65e | - | 0.030 | 0.030 | f | f | f |

| a | 0.50% maximum for copper, 0.50% maximum for nickel, 0.50% maximum for chromium, and 0.15% maximum for molybdenum. For grades up to and including L360/X52, Cu, Cr and Ni shall not be added intentionally. | ||||||

| b | For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for manganese is permissible, up to a maximum of 1.65% for grades = L245 or B, but = L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70. | ||||||

| e | Unless otherwise agreed. | ||||||

| f | Unless otherwise agreed, the sum of niobium, vanadium and titanium concentrations shall be = 0.15%. | ||||||

| MECHANICAL REQUIREMENTS | |||

| Weld seam of EW, SAW and COW pipes | |||

| Y.Sa | T.Sa | ELONGATION | Tensile Strengthb |

| Mpa(psi) | Mpa(psi) | Mpa(psi) | |

| min | min | min | min |

| 485(70 300) | 570(82 700) | c | 570 (82 700) |

| a | For intermediate grades, the differencec between the specified minimum tensile strength and the specified minimum yield strength for the pipe body shall be as given in the table for the next higher grade. | ||

| b | For Intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determines for the pipe body using footnote a) | ||

| c |

The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be as determined using the following equation: |

||

We are the manufacturers of various grades of metals which are being produced in different specifications such as carbon steel, alloy steel, stainless steel, duplex stainless steel, special alloy, seamless pipes and tubes.

We are producing different types of metallic grade products which are being providing support in construction needs and pipe fittings in various aspects.

上一篇:Welded Pipes - API 5L Gr.B,EN 10217,DIN 24338,EN 10305,EN 10

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) .

Hot Click PRO

-

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe