Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

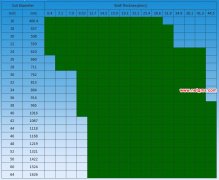

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

API Weight Drill Pipe 3-1/2"-6-5/8"

API Weight Drill Pipe 3-1/2"-6-5/8"

1. api drill pipe

1.OD.: 21.3mm-609mm WT.: 2mm-22mm 2.Material:H-40,J-55,K-55,N-80,C-75,L-80,C-90,C-95,P-110,Q-125

The wall thickness of heavy weight drill pipe is between drill pipe and drill collar,its structure is simliar with drill pipe.It is made from premium alloyed steel.Its both tool joints and middle upset are welded hardbands.Technical parameters meet with API Spec7-1 Standard.+

Thechnical specifications and parameters..

|

Size |

Tube OD |

Tube OD 1 |

Tool Joint OD |

Tool Joint OD |

Connection |

Max Elevator Upset Dia |

Center Upset Dia |

Min Drift Dia3 |

|

|

|

|

|

|

|

Deu |

Dcu |

|

|

3 1/2 |

3 1/2 |

2 1/4 |

4 3/4 |

2 1/4 |

NC 38 |

3 7/8 |

4 |

2 |

|

2 1/16 |

2 1/16 |

1 13/16 |

||||||

|

4 |

4 |

2 1/2 |

5 1/4 |

2 1/2 |

NC 40 |

4 3/16 |

4 1/2 |

2 1/4 |

|

2 9/16 |

2 9/16 |

2 5/16 |

||||||

|

4 1/2 |

4 1/2 |

2 11/16 |

6 1/4 |

2 11/16 |

NC 46 |

4 11/16 |

5 |

2 7/16 |

|

2 3/4 |

2 3/4 |

2 1/2 |

||||||

|

2 13/16 |

2 13/16 |

2 9/16 |

||||||

|

5 |

5 |

3 |

6 5/8 |

3 |

NC 50 |

5 1/8 |

5 1/2 |

2 3/4 |

|

5 1/2 |

5 1/2 |

3 1/4 |

7 |

3 1/4 |

5 1/2 FH |

5 11/16 |

6 |

3 |

|

3 3/8 |

3 3/8 |

3 1/8 |

||||||

|

3 7/8 |

3 7/8 |

3 5/83/4 |

||||||

|

4 |

4 |

3 3/4 |

||||||

|

6 5/8 |

6 5/8 |

4 |

8 |

4 |

6 5/8 FH |

6 15/16 |

7 1/8 |

3 3/4 |

|

4 1/2 |

4 1/2 |

4 1/4 |

||||||

|

5 |

5 |

4 3/4 |

||||||

|

1.Maximum tube ID is 1/8 larger than nominal.Minimum tube ID is controlled by the drift requirement. |

||||||||

|

Standard |

API 5CT,SY/T6194-96 |

|

Size |

OD:21.3-609MM WT:2-22MM Length:6-12m |

|

Material |

H-40,J-55,K-55,N-80,C-75,L-80,C-90,C-95,P-110,Q-125 |

|

Thread type |

LTC (long round thread casing connection) STC (short round thread casing connection) BTC(buttress thread) |

|

Length |

R-1:4.88~7.62m R-2:7.62~10.36m R-3:more than 10.36m |

|

Application |

Used in oil well drilling.It is mainly used for drilling process and after completion of borehole wall support, to ensure that the drilling process and the whole Wells after completion are normal running . |

| QB series Rod parameter-geological steel pipe-entire length thermal treatment, NC lathe with former cutters | |||||

| Spec. | Unit | BQB | NQB | HQB | PQB |

| OD/ID | mm | 55.6/46 | 71/60 | 89/77.8 | 114.3/101.6 |

| Thickness | mm | 4.8 | 5.5 | 5.6 | 6.35 |

| Length | m | 1.5 or 3 | 1.5 or 3 | 1.5 or 3 | 1.5 or 3 |

| Weight | kg/m | 6.01 | 8.8 | 11.51 | 17.3 |

| thread length | mm | 44.45 | 44.45 | 44.45 | 63.5 |

| thread pitch | thread/inch | 3 | 3 | 3 | 2.5 |

| box thread tooth height | mm | 0.76 | 0.76 | 0.76 | 1.17 |

| pin thread tooth height | mm | 0.88 | 0.88 | 0.88 | 1.27 |

| thread tooth angle | . | 29 | 29 | 29 | 29 |

| tensile resistance(A series) | kn | 400 | 530 | 510 | 565 |

| tensile resistance(B series) | kn | 450 | 615 | 625 | 660 |

| bore depth | m | 1200 | 1000 | 900 | 800 |

| RQ series Rod parameter-geological steel pipe-entire length thermal treatment, NC lathe with former cutters | |||||

| Spec. | Unit | BRQ | NRQ | HRQ | PRQ |

| OD/ID | mm | 55.6/46 | 69.9/60.3 | 88.9/77.8 | 114.3/101.6 |

| Length | m | 1.5 or 3 | 1.5 or 3 | 1.5 or 3 | 1.5 or 3 |

| Weight | kg/m | 6.01 | 8.8 | 11.51 | 17.3 |

| thread length | mm | 42 | 42 | 41.91 | 63.5 |

| thread pitch | thread/inch | 3 | 3 | 3 | 2.5 |

| box thread tooth height | mm | 0.76 | 0.76 | 0.76 | 1.17 |

| pin thread tooth height | mm | 0.88 | 0.88 | 0.88 | 1.27 |

| thread tooth negative angle | . | 5 | 5 | 5 | 5 |

| tensile resistance(A) | kn | 450 | 525 | 545 | 565 |

| tensile resistance(B) | kn | 530 | 625.5 | 602 | 660 |

| bore depth | m | ||||

New Update Pipe List

-

Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) .

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe .

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe