carbon steel elbow,Forming carbon steel pipe elbow standard

Forming carbon steel pipe elbow standard operating procedure

We supply carbon steel elbows of different standards(ANSI;JIS;DIN).

eg. ASTM A234 WPB & ANSI B16.9

1) Items: elbows

2) Standards: SGP, STD, SCH40, SCH80, SCH160. and so on.

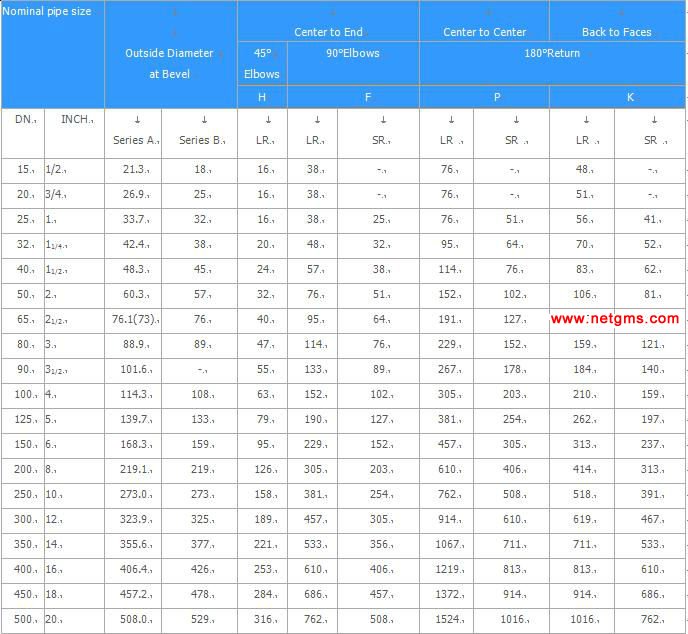

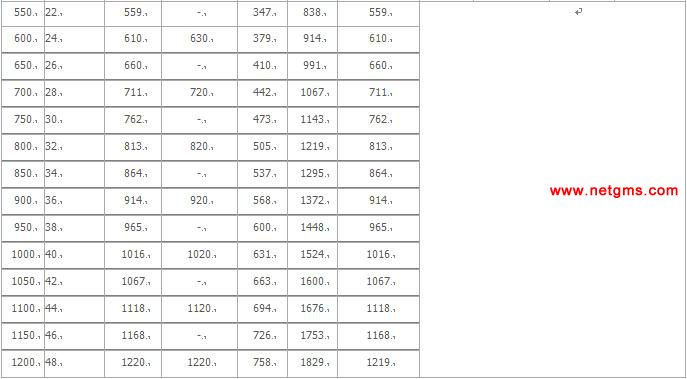

3) Size: 1/2"---72"

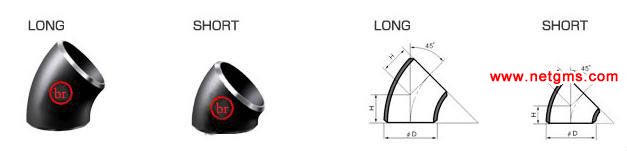

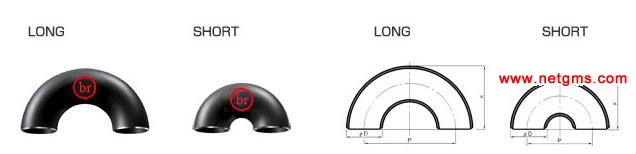

NAME:45 DEGREE BUTT-WELDED ELBOW

MATERIAL:A234-WPB.A420-WPL6.A234-WP12.A234-WP11.A234-WP5.

PRESSURE:Sch5-Sch160,XXS,XS,STD

STANDARDS: ISO. ANSI. JIS. DIN GB/T12459,GB/T13401,ASME B16.91

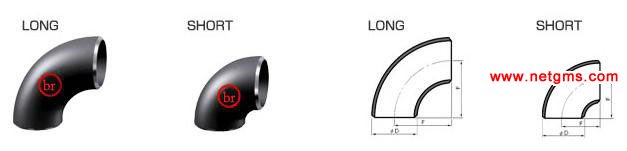

NAME:90 DEGREE BUTT-WELDED ELBOW

MATERIAL:A234-WPB.A420-WPL6.A234-WP12.A234-WP11.A234-WP5.

PRESSURE:Sch5-Sch160,XXS,XS,STD

STANDARDS: ISO. ANSI. JIS. DIN GB/T12459,GB/T13401,ASME B16.91

NAME:180 DEGREE BUTT-WELDED ELBOW

MATERIL:A234-WPB.A420-WPL6.A234-WP12.A234-WP11.A234-WP5L.

SIZE:1/2"-48",DN15-DN1200

PRESSURE:Sch5-Sch160,XXS,XS,STD

STANDARDS: ISO. ANSI. JIS. DIN. GB/T12459,GB/T13401,ASME B16.9

Found within the curved molding with wavy, pay attention to plate thickness is insufficient, such as iron thickness is not enough, re-cutting produced a new plate, forming a long time due to iron after thinning. If replacement of iron should pay attention to the first sheet of stainless steel, mat pad first come second iron molding pipe carbon steel pipe elbow 16 ", Japanese standard, 6mm sheet, have a heart mold bend thin metal plate.

Note: 1. Sheet thickness. 2 heart mold 3. Outer mold

Molding extension to rub oil pressure, pad tape.

Forming the first one to pay attention to both sides of the height is a standard size, the standard height of 5 ~ 6mm. For cutting. Size OK, pay attention oblique diagonal size is the same on both sides, the right size of the error, adjust the screws

If height is not the same, right high left is low, there is a lower mold height adjustment screw can be adjusted to the same height on both sides. Together forming, so that subsequent molding, OK after soldering iron to fix, after two previous lug, screw fixed to the upper mold position, sizzling position by screws depending on the time sheet iron lug mold may be, cutting Good height and welded.

Note that when forming the bend where there is wavy, then the fortress sheet or thin copper plate to flatten waves, or outside the arc integer integer mode, or when the upper die rose up call level. Welded stainless steel fixed plate below to protect, not to destroy and damage the surface, each a sheet metal forming, pay attention to whether a foreign body surface, wipe the surface of things, each one had to rub cast molding oil pressure, position the lower die port R portion, rub the outer extension of oil pressure within R watching molding R L / R or S / R inner circle R less oil rub, pay attention to the height on both sides after forming, shaping them pay attention.

If within the R wave molding can be used to pad thickness cardboard pack tape pressing plate material, there are two kinds of tape as follows:

1, the next bend cardboard long 2 short cardboard inside R Department, molding and then molding should rub molds, each had to clean not a foreign body in the mold, sheet metal forming surface when they had to check if there are problems, If scratched to immediately deal with, you can use a soft flat grinding wheel to deal with, groove at the wheel with a hard flat polished smooth and then use a soft grinding wheel grinding wheel handle or handle on behalf of, the surface can not have scratches and dents on the surface level grinding it matter dander around faster processing, then sent to the next process to molding.

2, note that when forming the inner and the outer curved bend can not have the appearance of scratches, scratched if not within the cut size, if you want to immediately re-polishing molding die next. After sending the next sheet cutting process, sanding edges after playing steel word, typing position away from the center of the plate at both ends between the right and left about 50 ~ 80mm position, and then turn it over sheet edges sanded finish, sheet would not turn back due to molding, steel word to be on the bottom, the operator should always pay attention to the surface, if the surface to be processed immediately good again bad shape.

Molding machine adjustment to the attention of the event:

1, the mold frame good upper and lower mold, trip switches rapid decline should be careful not to touch the plate material, rapid positioning to set off the sheet at a distance of about 50 ~ 100mm, and then slow down downhill, be careful not to let go of button halfway To reach place, and then slowly rise, and then slow down, back and forth three times plate material, then quickly rising in place, again at the bottom of cardboard and tape pad R, then quickly drop, direct the bottom, and then slowly increase pressure back and forth three times, then quickly rebounded, cardboard pad on the left and then pressed three times, and then press the right pad cardboard and tape three times, the rapid rise is complete.

2, the machine frame mold, to note the center, so that mechanical force can not be greedy convenient average deviation from the machine center for mechanical life is not good. Molded pipe carbon steel pipe elbow must pay attention to internal and external surface scratches and clean sheets to be clean, and pay attention to the height of each sheet should be a good rub, the completion of each work order card to pay attention to the next step of the process and the work area under a . 10 ", 12" to the mold base molding upside down to swap to molding, 14 "~ 36" on the mold base are in it.

Sheet material 6mm or less, have increased pressure pad twice and then tape to then pressed twice, pay attention to the bend of the waves, if the wave, have a thin metal pad to molding. 22 "~ 36" sheet bend in the molding waves will be very bad shape, if you can beat with a hammer waves waves waves to immediately deal with, there will be wave soldered bend clear microwave waves should be noted. 45 ° pipe carbon steel pipe elbow port diameter, integer with mold and lower mold 45 ° is removable screw adjustment. carbon steel pipe elbow integer when the first ship mold pressure inside, outside and back through-bore extrusion mold, such as size is too small then adjust down.

Three large-diameter outer mold is pressed first with the caliber, the diameter of depression and then beat the entire diameter size, can not be adjusted and then jacking wood, square wooden pillar dimensions.

Shaping diameter, the upper die to die first groove weld grinding, the whole ditch, lower die also need to grind the weld groove, position the front portion and the rear end portion of the intermediate goes.

上一篇:Welded Steel Pipe Inventory

下一篇:API 5L steel pipe,API 5L standard terminology

Seamless steel pipe

Seamless steel pipe Welded steel pipe

Welded steel pipe Carbon steel pipe

Carbon steel pipe Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings